Massachusetts Company Uses Bacteria to Create Sustainable Fuel

Fossil fuels are dirty business, from exploration to consumption and every step in between, but one Massachusetts-based company is looking to revolutionize the energy industry by pioneering a new way to farm sustainable fuel.

“We produce ethanol, diesel and jet fuel,” said Tom Jensen, Joule’s executive vice president and head of corporate development, through a process that he described as industrialized photosynthesis. Compared to traditional petroleum their products have a 90 to 100 percent smaller carbon footprint meaning, “It’s a CO2-neutral fuel.”

SEE ALSO: What is Octane?

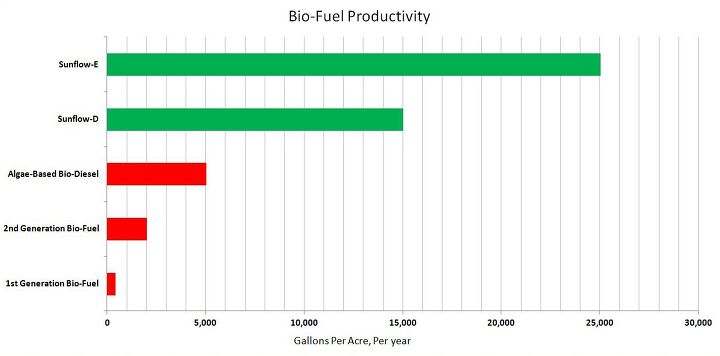

Contrasting Joule’s stuff to rival energy sources is eye-opening. Jensen said their Sunflow fuels are an order of magnitude more efficient than even second-generations of competing technologies. According to him, a first-gen bio fuel is capable of yielding about 400 gallons per acre, per year. A second-generation might increase output to 2,000 gallons per acre, per year, while algae-based bio-diesel might be as productive as 5,000 gallons annually.

But Joule’s system far outpaces these levels. Their diesel process can yield 15,000 gallons per acre-year and their ethanol system is even more fruitful, delivering about 25,000 gallons annually. Jensen said, “Nobody can do what we can do in terms of converting CO2 into drop-in fuels,” that is, liquid energy that’s essentially ready to go right into your car or truck’s tank.

Dirty Business

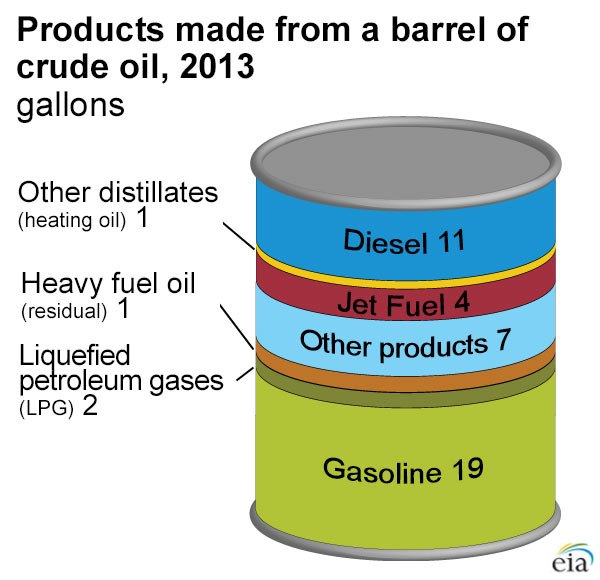

For a little context, refiners get about 11 gallons of diesel from a barrel of crude oil. Taking our average daily petroleum consumption and multiplying it by that figure means America burns roughly 209 million gallons of diesel every day. In comparison Joule’s production process yields approximately 41 gallons of this stuff per acre per day. So, in order for them to offset just 10 percent of our daily diesel consumption, which works out to a little less than 21 million gallons, they’d need a skosh more than 512,000 acres of land. With 640 acres to a square mile that works out to roughly 800 square miles, a space two-thirds the size of Rhode Island. Accordingly it seems unlikely they’d ever be able to scale things up that far meaning Joule’s energy will likely only supplement oil, not replace it.

Still, concerns about CO2 emissions, climate change, hydraulic fracturing and related issues are hastening the need for earth-friendly energy. Joule has been developing its technology since 2007 and according to Jensen it’s “by no means a trivial feat.”

Audi-motive Partnership

And fortunately for them they’ve received some help from the automotive sector. As one of Joule’s partners, Audi is lending them a hand in several ways. “We can help them financially a little bit,” said Sandra Novak, regulatory engineer at Volkswagen Group of America. “It is also good to have some famous brand next to you,” she added, in order to “draw some attention.” It seems Audi’s global presence and sterling reputation can only help Joule as it looks to revolutionize the fuels industry while simultaneously helping the environment.

Carbon dioxide is a big concern these days as it’s a powerful greenhouse gas. Fortunately Joule’s process requires a steady stream of CO2. For consistent supplies they’re planning on locating future production facilities near big carbon sources like coal-fired powerplants or cement factories where they can tap into flue gases that would normally be vented to atmosphere. Obviously this is beneficial for them and planet earth.

Challenges on the Horizon

Sure, diesel provides plenty of benefits over gasoline including 20 percent better fuel economy, abundant low-RPM torque and mechanical longevity, but the added cost of these cars and trucks is hard for many customers to bear. Additionally, gasoline prices have been tumbling lately, something that makes diesel an even more difficult proposition since it’s usually about 20 percent more expensive.

SEE ALSO: What is E85?

And then there’s ethanol. Whether corn-based or derived from cellulose this alcoholic fuel always seems to start a firestorm of controversy, both political and otherwise. Aside from being up to 30 percent less energy dense than straight gasoline, something that results in significantly lower fuel economy, it’s also quite corrosive, something can cause all kinds of problems in older vehicles.

Proof in the Pudding

But none of these downsides are preventing Joule from developing its processes. And fortunately for them the energy they’ve been producing is rock solid.

Aside from providing funds and a wholesome image, Audi is also helping this ambitious company evaluate their products. Novak said, “We are doing the verification of the fuel in the engine.” Based on the data they’ve gathered so far, “It looks really good, it’s really promising,” she said.

They’ve been rigorously testing Joule’s goods and according to Novak, they’ve had no issues with them, but she said they’re still evaluating. “The main focus right now is ethanol, but Joule is also working on diesel.”

Growing Fuel, One Drop at a Time

Aside from causing sinus infections or helping make yogurt these critters are absolutely vital to life on earth, performing more biological functions than can be listed. They’re also the engine that enables Joule to literally grow fuel.

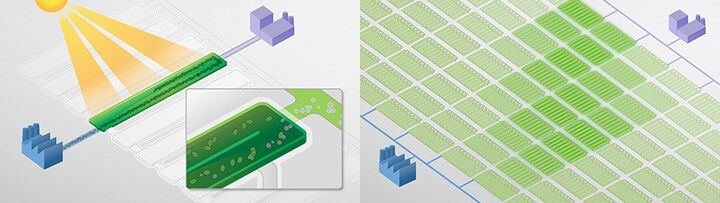

“Nature has for billions of years … developed photosynthetic processes,” Jensen said. Simplifying things, certain organisms use carbon, water and energy from the sun to produce oxygen and biomass. What Joule has done is tailor this process to make fuel.

But pond scum can’t produce bio-fuel on its own, which is where Joule’s engineers stepped in to create special versions of this microorganism. “It is a bacteria that we have significantly strengthened, let’s call it a super bacteria,” said Jensen. “We turn them into [a] bio-catalyst; they are catalyzing the CO2 into bio-fuel.”

Desert with an Ocean View

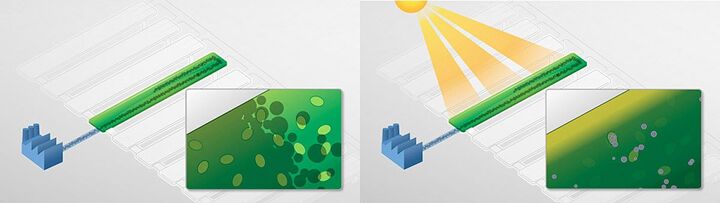

Joule’s custom cyanobacteria reside in special water-filled homes or closed bioreactor systems, “basically plastic tubes,” as described by Jensen. They’re parked outside where they receive a daily blast from the sun, and they get plenty of that at company’s pilot plant.

Located in Hobbs, New Mexico, which is roughly 110 miles south-west of Lubbock, Texas, this facility’s desert location is ideal for several reasons. First, it gets lots of sunshine but it also doesn’t take up any land that would be suitable for farming.

However, there is one issue. Water can be hard to come by in arid regions. Fortunately this shouldn’t be a problem for Joule. “We need water,” said Jensen “but not fresh water.” Their cyanobacteria thrive in brackish or saline conditions.

And that’s just the beginning. “Compared to crop-based bio-fuels we need 100 times less water,” Jensen said. They also don’t compete for arable land. These are two huge advantages, especially when compared to corn-based or even cellulosic ethanol.

Normally plants take in water, sunlight and carbon dioxide to grow, but Joule’s engineers have modified this formula slightly and the results are profound. According to Jensen, “We have shut off the organism’s ability to reproduce.” Instead, all they do is secrete fuel, they’ve been “specifically designed to do as efficient a CO2 conversion as naturally possible.”

Essentially Joule has figured out how to neuter the cyanobacteria by injecting a secret chemical into the water they live in. Instead of multiplying as they would normally with adequate resources, Joule’s cyanobacteria focus all of their energy on producing either ethanol or bio-diesel, fuels that are referred to by the company as Sunflow-E and Sunflow-D, respectively. Of course these critters release oxygen as well, which is good for everyone.

However, this isn’t the limit of what Joule’s cyanobacteria can do. Kerosene, plastics and other components could be also secreted but Jensen said, “For now we’re focused on fuel.”

When it comes to producing either ethanol or diesel the difference comes down to the bacteria used. “It’s the same chassis,” explained Jensen, it’s just a different catalyst. “The bug itself that we put into the system, it will be either an ethanol organism or an alkane organism.”

Fueling the Future

By the end of this decade there should be commercial quantities of Joule fuel available on the market. For the time being they’re focusing on ethanol but Jensen said “diesel will follow rapidly after that.”

To make this goal a reality they’re expanding their plant in New Mexico but going forward Jensen said, “We will most likely commission our first commercial-scale facility in the next couple years.”

Check out our Tips and Advice section!

Born and raised in metro Detroit, Craig was steeped in mechanics from childhood. He feels as much at home with a wrench or welding gun in his hand as he does behind the wheel or in front of a camera. Putting his Bachelor's Degree in Journalism to good use, he's always pumping out videos, reviews, and features for AutoGuide.com. When the workday is over, he can be found out driving his fully restored 1936 Ford V8 sedan. Craig has covered the automotive industry full time for more than 10 years and is a member of the Automotive Press Association (APA) and Midwest Automotive Media Association (MAMA).

More by Craig Cole

Comments

Join the conversation

Better than Hydrogen.