Ford Teams With 3M and GE Healthcare to Produce Respirators and Ventilators

In the midst of the global pandemic caused by COVID-19, Ford along with many other manufacturers announced that it has temporarily suspended vehicle production in multiple regions.

For the latest information on the COVID-19 pandemic, make sure to check the World Health Organization website.

The American giant also announced that it will be teaming up with 3M and GE Healthcare to manufacture urgently required medical equipment. The healthcare workers at the front lines of this pandemic have been fighting the disease and dwindling supplies. Ford is scaling up production to produce respirators, ventilators and face shields. It’s using designs from 3M and GE and off-the-shelf parts from its own catalog.

Ford and 3M

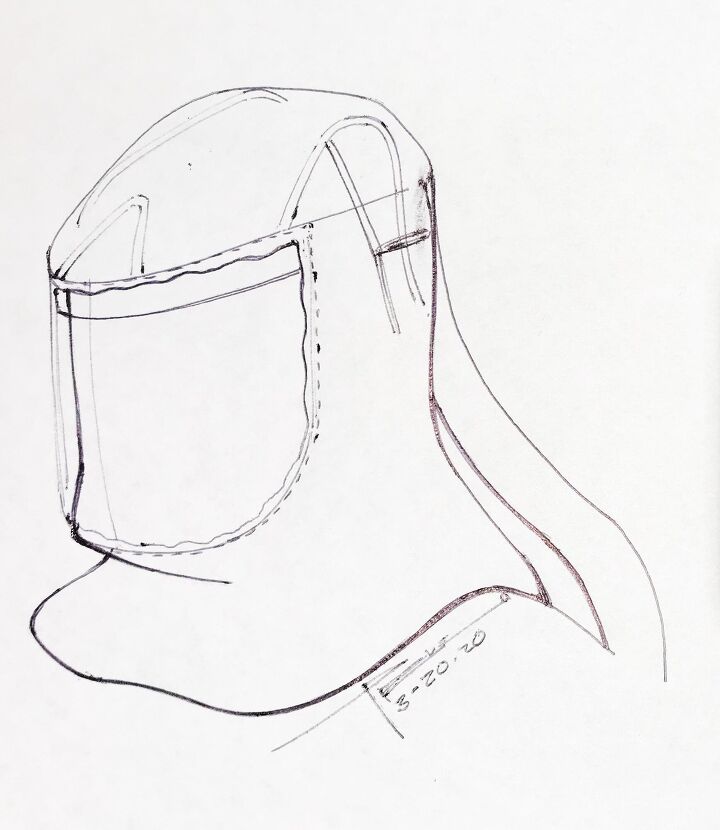

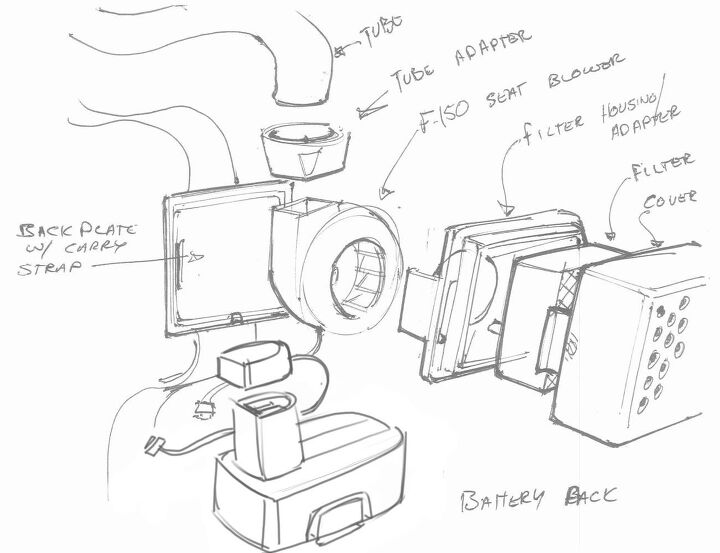

Ford and 3M have joined hands to produce a new powered air-purifying respirator, or PAPR for short. It is based on 3M’s existing design. A PAPR is a battery-powered device that actively filters out pathogens and droplets that might carry viruses. It comprises an airtight face shield that is hooked up to an air tube. The tube connects the mask to a console that controls the airflow. Given the urgency, Ford and 3M are looking at producing the new-generation PAPR with parts already at hand. For instance, the team will utilize the fan from the cooled seats of the F-150 light-duty truck. The filter will be 3M’s own HEPA filter and the portable battery will keep the PAPRs running for up to eight hours.

Ford could produce the respirators at its facility with the help of UAW workers. This would increase 3M’s manufacturing capacity tenfold.

SEE ALSO: How To Keep Your Car Contagion Free“Working with 3M and GE, we have empowered our teams of engineers and designers to be scrappy and creative to quickly help scale up production of this vital equipment,” said Jim Hackett, Ford’s president and CEO. “We’ve been in regular dialogue with federal, state and local officials to understand the areas of greatest needs. We are focusing our efforts to help increase the supply of respirators, face shields and ventilators that can help assist health care workers, first responders, critical workers as well as those who have been infected by the virus.”

Ford and GE Healthcare

Ford is also working with GE Healthcare to produce a simplified version of GE’s ventilator as fast as possible. The ventilator is a critical component in the fight against COVID-19. It helps lung function in people experiencing difficulty breathing or outright respiratory failure.

GE Healthcare President and CEO Kieran Murphy said. “We are proud to bring our clinical and technical expertise to this collaboration with Ford, working together to serve unprecedented demand for this life-saving technology and urgently support customers as they meet patient needs.”

SEE ALSO: Coronavirus: All the Deals and Support Programs Automakers are OfferingFord plans to utilize its in-house resources to produce 100,000 face shields per week. The first 1,000 face shields are set to be tested at the Detroit Mercy and Detroit Medical Center hospitals. Ford aims to produce 75,000 shields just this week and then 100,000 per week after that. The full face shield coupled with the N95 Respirator will be a strong first defence against the coronavirus. It isn’t clear however if Ford will be making the N95 respirators, but it is helping hospitals locate critical supplies, including them.

The Blue Oval joins FCA in producing vital health supplies during this ongoing pandemic.

More by Kshitij Sharma

Comments

Join the conversation