What's the Best All-Wheel-Drive System for You?

More and more automakers are offering all-wheel-drive than in the past. This extra choice is great news for consumers but it can lead to confusion; the number of technologies on the market is practically vertigo-inducing. Each manufacturer’s system is unique, and a lot of times the underlying hardware is different. Not every all-wheel-drive setup was created equally. Which one is best for you? Here’s an overview of what some major manufacturers offer.

“There are two basic vehicle architectures out there today,” said Mark Barrett, the Group Vice President of Engineering, Product Development and Procurement at American Axle (AAM). How the engine is mounted in a vehicle is “really what defines that high-level architecture.”

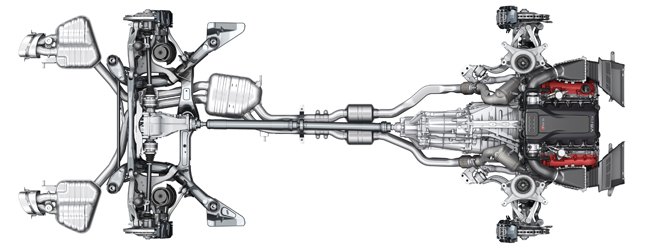

Engines can be positioned transversely (side to side) like they are in most front-wheel-drive vehicles or longitudinally (front to back) as in rear-wheel-drive cars and trucks. Basically it’s how the power flows through a vehicle. Barrett said this is important because a, “transverse engine configuration means you have to go 90 degrees to transfer the torque to the rear.”

A power transfer unit (PTU) is needed to turn that corner in the driveline. According to Barrett, a PTU is “essentially a gearbox” that sends torque rearward. It’s the foundation of an all-wheel-drive configuration used by many manufacturers today. Vehicles like the Honda CR-V and Ford Fusion feature systems like this.

All-wheel drive that’s paired with a longitudinally mounted engine tends to be more traditional, like something you’d find on a full-size SUV. These systems usually feature a transfer case to send power to the front axle and a defined torque-split front to rear. But this layout is not only for trucks. The new Cadillac ATS sports sedan has a longitudinally mounted engine and an available all-wheel-drive system provided by AAM. Also, the Chrysler 300 and Dodge Charger full-size sedans offer a very similar part-time all-wheel-drive setup.

AAM provides individual components to automakers, but in most cases “we do the whole driveline system,” Barrett said. This is advantageous compared to the piecemeal approach because, “sometimes the parts don’t function as well as they should.” There can be noise or vibration issues and doing it separately can actually cost more.

“We supply a lot to GM, on their Opel Insignia, Cadillac SRX all-wheel-drive [and] Buick Regal all-wheel-drive,” Barrett said, but Detroit is not their only customer. AAM’s European operations provide a torque-transferring center differential to Audi for its advanced, driver-focused quattro system.

‘ROUND THE CLOCK, AROUND THE BLOCK

Aside from how the engine is mounted in a vehicle there are other ways to classify all-wheel-drive layouts. According to Barrett, full-time systems feature a defined torque-split front to rear and are always on and available to work.

“The driver doesn’t have to do anything,” he said, which is an advantage of this layout. One downside though is that constantly spinning all of those extra components creates friction and reduces fuel economy. Generally, full-time systems seem to be more performance oriented, or found on trucks. Mitsubishi’s small and speedy Lancer Evolution uses this technology as does the ferocious Nissan GT-R.

ON-CALL-WHEEL DRIVE

Unlike its full-time brother, part-time all-wheel drive only powers four wheels when slippage is detected. This reduces parasitic losses and boosts fuel economy. “Every tenth of a mile per gallon is critical,” Barrett said, noting that OEMs are battling to minimize consumption. He also said when you go from front-wheel drive to all-wheel

These systems seem a lot more common than their always-on siblings. The Ford Explorer features a part-time system as does the Nissan Murano and Rogue. In the name of fuel economy, Acura switched to a part-time setup when it redesigned the RDX crossover for 2013.

FOUR RINGS, FOUR TIMES THE FUN

Arguably the industry leader in all-wheel drive is Audi. The German automaker introduced its famed quattro system in the spring of 1980 on a two-door car of the same name. It was the first volume-built permanent all-wheel-drive setup suitable for sporty vehicles, and that focus on driving performance continues today.

On the first-generation quattro system torque was split evenly between the front and rear axles. Under its boxy hood sat a longitudinally mounted engine, but the car featured at least one major innovation: a bevel-gear center differential. This complex-sounding part pulled double duty, directing power to the car’s front wheels and eliminating the need for a transfer case and auxiliary shaft, two heavy and complicated components.

In its day the quattro was quick and responsive, a Cold War driving sensation. Owners could also manually lock the center and rear-axle differentials for better traction on slippery surfaces.

When Audi develops a new vehicle, quattro is included from day one, something its competitors don’t necessarily do. In the words of Mark Dahncke, Product and Motorsports Communications Manager for Audi, competing systems are “engineered into the platform after the fact.” He said including all-wheel drive from the start gives Audi “a very, very cohesive system” that “works together.”

How these systems are attached to a vehicle’s powertrain is a big deal too, and Dahncke said they’ve got the manufacturing experience to bring everything together in a unified package, similar to AAM’s one-stop-shop approach.

“Frankly it’s the most expensive system,” Dahncke said, noting that quattro is still mechanical, “not just an electronic chip.” It’s always engaged — a true full-time system — shuffling engine torque from axle to axle and wheel to wheel, maximizing grip and minimizing slip. But Audi is not the only game in town.

THE BEAUTY OF SYMMETRY

Subaru proves there’s a lot more to all-wheel drive than just four wheels turning. Audi’s cross-hemisphere rival prides itself on delivering this technology to a mass market.

“It’s standard on all of our vehicles except the BRZ,” said Dominick Infante, National Manager Product Communications for Subaru of America, Inc.

In a move similar to what Audi does, Infante said, “all of our cars are designed to be all-wheel drive,” noting that they engineer it into vehicles from the get-go. Subaru calls its system “Symetrical All-Wheel Drive” because of how it sends the power to the wheels.

Competitors often retrofit all-wheel drive onto existing front-wheel-drive vehicles. With a transverse-mounted engine torque has to be transmitted around corners to drive the wheels, which complicates things and reduces efficiency – not so with Symmetrical All-Wheel Drive.

Subaru has several different versions of its system. Cars equipped with manual transmissions feature a set 50:50 torque split front to rear. Models powered by their 3.6-liter six-cylinder engine use a different setup known as a Variable Torque Distribution system – VTD for short. Subarus with continuously variable transmissions use yet another version, as does the outrageously quick WRX STI. Interestingly the STI allows drivers to choose how the torque is split between the front and rear axles so they can customize how the car behaves, whether they’re navigating a snow-covered mountain road or bombing around a race track.

Despite these different technologies Infante said, “we only have full-time all-wheel drive,” contrasting it with some of the competition’s systems that aren’t as robust and can’t put as much torque to the rear wheels. “With Subaru everything has to be a little bit overbuilt” he said. “It’s kind of the Subaru way.”

“X” MARKS THE SPOT

Swapping sushi for spätzle, another one of Germany’s automotive crown jewels has its own take on all-wheel drive. BMW has earned a reputation for building cars with unassailable dynamics, and its xDrive system lives up to this standard.

A full-time setup, it features a defined torque split favoring the back axle. Under normal conditions either 60 percent or 80 percent of the torque is sent to the rear wheels, depending on the vehicle.

When conditions dictate, xDrive can deliver all of the engine’s torque to the back tires and at least 50 percent of it can be shuttled to the front axle for extra grip in slippery situations.

In keeping with current industry trends, General Motors overwhelmingly favors part-time all-wheel drive. In fact, the only vehicles in its vast stable that are offered with a full-time system are big trucks – the Cadillac Escalade, GMC Yukon Denali and Yukon Denali XL.

All other systems the company offers are on demand – they only engage when wheel slippage is detected.

WHAT’S YOUR VECTOR, VICTOR?

An interesting all-wheel-drive advancement is called torque vectoring, something that can really improve how well a vehicle handles. It’s a complicated sounding name for something that’s fairly straightforward.

Both Audi and Acura employ torque vectoring, the former with its optional rear sports differential and the latter courtesy of something known as Super Handling All-Wheel Drive.

Taking a peek at Acura’s SH-AWD technology on the TL luxury sedan, it keeps up to 90 percent of the engine’s torque at the front wheels during regular driving. This helps minimize friction to maximize fuel economy. During hard acceleration 45 percent of the power can be sent to the rear axle for better traction. Pretty standard stuff, but SH-AWD really comes into its own on twisting roads.

During hard cornering and acceleration, up to 70 percent of the available torque can be directed to the rear, but all of that can be funneled to just the outside wheel if necessary. This helps the car rotate as it turns, minimizing understeer and keeping it headed where the driver intends.

STEP BY STEP (DAY BY DAY)

Automakers are doing everything they can to improve the efficiency of their vehicles. The move to part-time all-wheel drive instead of full-time setups is a small step to higher fuel economy. The next tread on the MPG staircase is disconnecting the system altogether when it’s not needed.

If a large part of an all-wheel-drive assembly can be completely shut down when extra traction is not required, parasitic losses can be minimized. AAM’s upcoming EcoTrac™ technology does just that. It stops the PTU, prop shaft and part of the rear drive module (RDM) from spinning unnecessarily. Altogether it’s a patented design.

“We’re going to be the first in the industry to launch this EcoTrac™ disconnecting all-wheel-drive system in the second quarter of 2013” Barrett said. What he did not say is which automaker will be using the system, only hinting that it’s a major global OEM whose products are sold in North America, Europe and Asia.

A disconnecting all-wheel-drive system is not without its challenges. Barrett said “[there’s] a lot of energy to control.” Imagine all those heavy, robust drivetrain components are stationary, when the vehicle needs some extra traction they have to spin up to highway speed in just milliseconds, and they have to do it absolutely transparently, without the driver ever knowing. Not an easy task. “How you make all that work together is very important,” and AAM has it figured out he said.

ALL-WHEEL-DRIVE BY WIRE

Like hybrids supplanting traditional internal-combustion engines, electricity will probably bring about the final development of all-wheel drive. It seems inevitable that motors, wires and battery packs will replace the heavy and complicated series of shafts, clutches and differentials that make the technology possible today.

In fact, this is already being done. In Europe French automaker Peugeot sells an electrified version of its 3008 crossover called the HYbrid4. Its front wheels are powered by an efficient diesel engine but the rears are driven purely by electricity – no mechanical links connect the front and rear axles.

In this application an electric motor delivers all-wheel-drive performance with hybrid fuel economy. It’s really the best of both worlds.

Acura is also implementing a similar system. Its 2014 RLX flagship sedan is expected to debut with a new Sport Hybrid Super Handling All-Wheel Drive system. Similar to what Peugeot is doing, Honda’s luxury division is amping up the car’s rear end. It will feature two electric motors, one driving each wheel – no mechanical bits will connect the front and back of the car. Acura’s Sport Hybrid SH-AWD technology should hit the market in late 2013.

Not to be left out of the party, AAM is also developing a similar system called eAWD. Barrett said it’s the “next evolution of all-wheel drive.” It’s modular and easily scalable, meaning “it could be made to work on any vehicle platform,” he said.

Hybrids would be the perfect application for eAWD because they already have a battery pack onboard. If the system were adapted to other vehicles they would need a battery or a generator to power the electric motor.

Packaging is a major advantage of these electric all-wheel-drive systems. Without clutches and prop shafts and differentials (oh my) they’re very compact and much easier to fit underneath a vehicle.

ALL WHEELS, ALL THE TIME

All-wheel drive is like an ice-cream sundae for motorists. Improved traction is the creamy foundation, greater safety the delicious hot fudge, and peace of mind the cherry on top. It’s a tasty treat more and more drivers are opting for.

“The percentage of usage of all-wheel-drive systems is going up,” Barrett said. Anywhere from 5 to about 25 percent of new-vehicle buyers opt for the technology, figures dependent on model, platform and manufacturer, of course. Based on current trends, AAM sees the take rate increasing to between 25 and 50 percent, or more, over the next five years. Pickup trucks are already leading the charge. Right now about 50 percent of them are purchased with some sort of four-wheel drive.

At the end of the day the right system for you depends on your vehicular needs. If you’re looking for a spacious and efficient crossover that can handle snowy roads, part-time is just about your only choice. Pickups and truck-based SUVs usually offer proper four-wheel-drive systems for serious off-roading. But if performance is your thing, driver-focused vehicles tend to offer less-efficient but sportier full-time all-wheel drive.

Here’s a list of popular vehicles on the market today. They’ve been sorted into two groups based on the type of all-wheel-drive system they come with — either part-time or full-time.

Part-Time All-Wheel Drive

Hyundai Santa Fe (driver-lockable full-time four-wheel drive)

Jeep Compass (with Freedom-Drive I)

Jeep Patriot (with Freedom-Drive I)

Nissan Pathfinder (with full automatic or driver selectable two-wheel drive and four-wheel drive modes)

Full-Time All-Wheel Drive

Acura (SH-AWD)

Audi (quattro)

BMW (xDrive)

Dodge Durango (HEMI-powered models feature a low-range transfer case for full four-wheel drive)

Jeep Grand Cherokee (with Quadra-Drive II, Quadra-Trac I or Quadra-Trac II)

Jeep Liberty (with driver-selectable Selec-Trac II system)

Subaru (Symmetrical)

2013 Toyota RAV4 (driver-lockable part-time system)

Correction: Barrett said switching from front-wheel drive to all-wheel drive reduces efficiency by about two miles per gallon, not 2 percent as initially reported.

Born and raised in metro Detroit, Craig was steeped in mechanics from childhood. He feels as much at home with a wrench or welding gun in his hand as he does behind the wheel or in front of a camera. Putting his Bachelor's Degree in Journalism to good use, he's always pumping out videos, reviews, and features for AutoGuide.com. When the workday is over, he can be found out driving his fully restored 1936 Ford V8 sedan. Craig has covered the automotive industry full time for more than 10 years and is a member of the Automotive Press Association (APA) and Midwest Automotive Media Association (MAMA).

More by Craig Cole

Comments

Join the conversation

You are a dork for not mentioning Mitsubishi's AWC.

Not even mentioning the name of Subaru in an AWD systems article is a shame...