2017 Acura NSX: Made in the USA

There’s no shortage of buzzwords to describe the new Acura NSX, but the truth is, it’s an ordinary yet high-tech supercar. That may sound strange, but a tour through Acura’s facility where they make this 573-horsepower mid-engine marvel helps demonstrate the point.

For starters, it’s not built in any exotic location. Unlike other supercars built in Europe or Japan the Acura NSX is built in Marysville, Ohio. In fact, Acura insists that this is the only supercar designed, developed and manufactured in the United States.

The Performance Manufacturing Center (PMC) in Marysville is where buyers can go and watch their six-figure car being assembled, not far from the same plant that makes the Honda Accord and has been since 1982 when Honda decided to start manufacturing its biggest sellers right in one of its biggest markets.

There’s a lot of Honda and Acura history in Ohio. The plant in East Liberty makes the CR-V and Acura RDX, while a plant in Anna makes engines and a plant in Russells Point makes transmissions and all-wheel drive components. There’s also the Raymond, Ohio Research and Development facility where many aspects of the Acura NSX were tested and developed.

See Also: Top 10 Things You Need to Know About the Acura NSX

Honda may have its headquarters in sunny California, but its muscle is spread out through the US, and here in Ohio, the Acura NSX isn’t just manufactured and assembled, but carefully crafted.

Robots and Humans Working in Harmony

Precision has always been a term used by Acura to describe the quality and finish of their vehicles, but here at the PMC, there’s a combination of man and machine that work in unison to make the Acura NSX the ultimate supercar the brand envisioned.

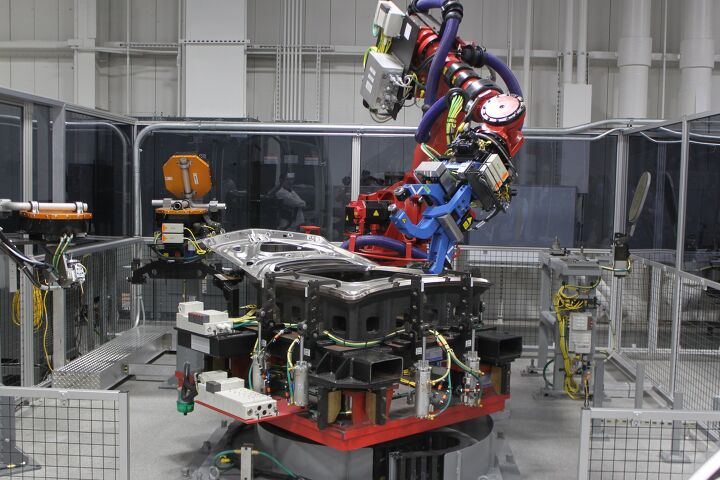

For starters, the vehicle’s lightweight space frame is completely welded by robots ensuring a consistent process every time. There are 860 welds to the multi-material frame, all applied by eight robots. The welds are then checked by skilled technicians, both visually, and using precise measurements to validate the accuracy. The tools can measure down to 50 microns, which is less than half the width of a human hair.

An all-glass quality confirmation center is found in the middle of the facility, so that technicians can see and monitor all aspects of the Acura NSX production. It’s this care and accuracy that helped Honda and Acura earn the amazing reputation for reliability that they have today. In many ways, the NSX is just like any other car the brand makes, but of course, with a higher pricetag, more exotic materials and higher limits of performance.

There’s an almost OCD level of perfection required here, and that makes sense seeing how the car costs well over $100,000 and owners not only expect an exceptionally crafted machine, but one that will be reliable and offer a world-class level of performance. That’s a tall order, but the folks at the PMC seem up to it, and even the ones who aren’t at the center are contributing to each Acura NSX in a big way.

Planning the Power Plant

Consider the Master Builders at Honda’s Anna Engine plant, putting together the 75-degree, twin-turbo V6 engine by hand. It takes over six hours to make the engine, and each engine maker follows their engine from the beginning of the process to end. Their fingerprints are all over the power plant, literally, with each of the engine’s 547 bolts being hand started and then manually tightened to precise torque tolerances. To keep quality in check, Honda has high-tech torque wrenches that record the individual torque of each bolt on each car, so measurements can be tracked down in case of an issue.

Those engines are also broken in to the tune of 150 miles, and individually balanced ensuring perfection by the time the car reaches the customer. The idea for this highly precise and technical build comes from Honda’s race engineering background.

One of the few components not developed here in the US is the nine-speed dual-clutch transmission, which is made in Japan. It’s crafted, benchmarked and broken in a similar manner to the engine.

Panels Last

Due to the space frame design, the exterior panels are applied during the final phases of manufacturing. Before they’re applied though, they have to be painted with 11 coats including primer. There’s also an extensive polishing and substrate preparation, which gives the car its shiny glow. The painting process takes place in a glass room that Acura likens to a Polar Bear exhibit in the zoo, so customers can see their car’s panels get individually painted.

Again, items are visually inspected before being applied to the car and important bolts are hand started and then individually torqued and measured. Once everything is put on the car, some very important and detailed inspections take place.

Testing Everything

Those inspections include a 45-minute long alignment that uses a few neat Honda patented items, like a floating swivel-chair that allows the tech to inspect the suspension from under the vehicle. The wheel alignment procedure also includes a measurement device that fixes to the center cap of the wheel, rather than the rims where there’s a greater chance of scratching them. Technicians also do a four-corner weight and ride height check. Following that, the NSX is hooked up to a dyno where the brakes and throttle are calibrated.

Finally, there’s a very interesting road simulator, where the car is loaded onto four posts (one for each wheel) that can simulate a smooth road, with elevation changes. It can even simulate potholes, and while that may be an unreasonable place for other exotics, the NSX seems to be an every-day kind of supercar. Think of this final check as a shake-down, just without needing the road. It will help point out any rattles.

The Experience

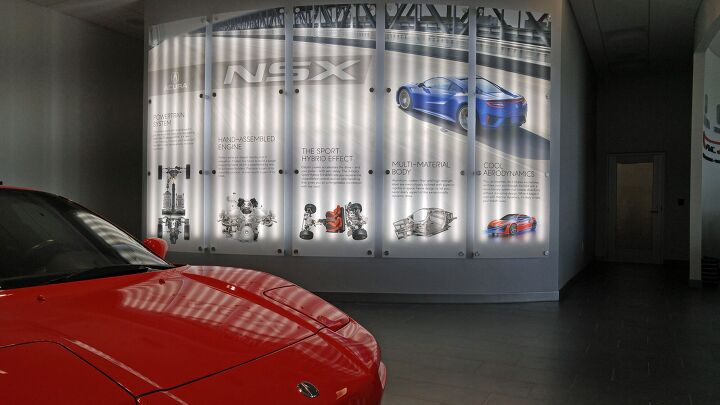

Mass production of the NSX starts at the end of April, and Acura estimates that they can make at least eight units a day. Since customers are expected to be touring the plant, it’s clear the automaker is looking to wow guests. In the lobby is a pre-production NSX, with a pristine first-generation Zanardi edition NSX close-by. The sliding doors into the facility are frosted, and can go clear with the flick of a switch demonstrating Acura’s dramatic flair. Close to the center is the Heritage Center, where guests can learn all about the lineage of Honda and how the brand came to be, including its success in the US.

See Also: 2017 Acura NSX Review – Video

There’s no doubt that the NSX is a special car. It’s built with space-age technology and high-end materials that have extraordinary limits. But the mindset at Honda is to create a process that works on a small scale and apply it on a larger one. With the NSX and the Performance Manufacturing Center in Ohio, it’s clear that there are certain building blocks in place for the future of the company, using what they learned from their previous manufacturing plants to ensure this plant can pump out this impressive machine.

Marysville Ohio may not be the exotic location that supercar buyers would expect. It doesn’t really compare to Maranello or Sant’Agata Bolognese, Italy or even Affalterbach, Germany. But at the end of the day, the NSX is still a world-class performance machine that can keep up with the likes of the best of them, all while being practical every day and built with the same precision and care that made Honda and Acura household names today.

Discuss this story at our Acura NSX Forum

Sami has an unquenchable thirst for car knowledge and has been at AutoGuide for the past six years. He has a degree in journalism and media studies from the University of Guelph-Humber in Toronto and has won multiple journalism awards from the Automotive Journalist Association of Canada. Sami is also on the jury for the World Car Awards.

More by Sami Haj-Assaad

Comments

Join the conversation

cool stuff