How Does a CVT Work?

Automatic transmissions are HUGELY popular in North America. Europe is still a strong hold for the manual gearbox but on this side of the Atlantic self-shifters account for at least 90 percent of new-vehicle sales; the standard trans lost the market-share race decades ago and in spectacular fashion.

And that final option is the one that raises the ire of true automotive enthusiasts like nothing else this side of hybrids. If these folks don’t have three pedals and a mechanical ratio-selector to play with they just aren’t satisfied.

CVTs are a relatively new trend on the market; they promise better fuel economy and smoother driving, but how do they actually work? How can they change ratios without traditional gears? Is this automotive witchcraft or just common-sense engineering?

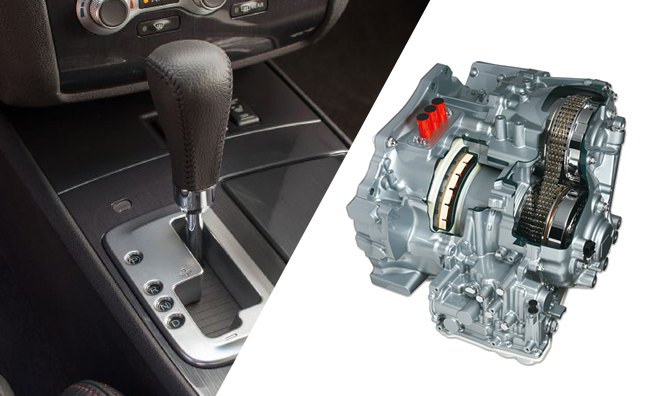

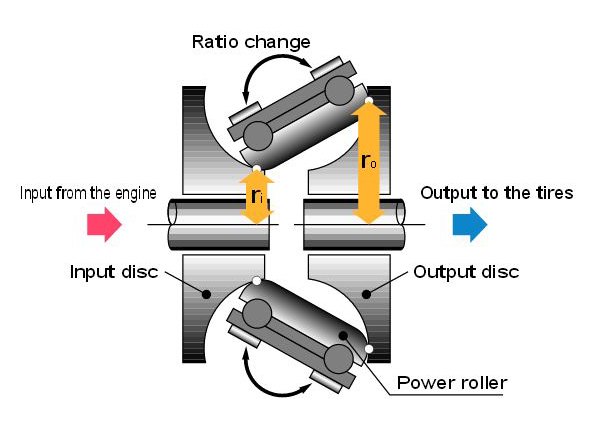

A LOOK INSIDE

Surprisingly there is a wide variety of different CVT designs out there, but for automotive applications many of them just aren’t practical. Pierre Loing, vice president of product, advanced planning and strategy at Nissan North America said “For us there is basically one system, which we use in different sizes and executions… for transversely mounted applications.”

Of all the automakers in North America Nissan has probably been the most aggressive in pushing CVTs. The technology has proliferated throughout their lineup in recent years and you can get one in vehicles ranging from the tiny Versa Note hatchback all the way up to the hefty Pathfinder crossover.

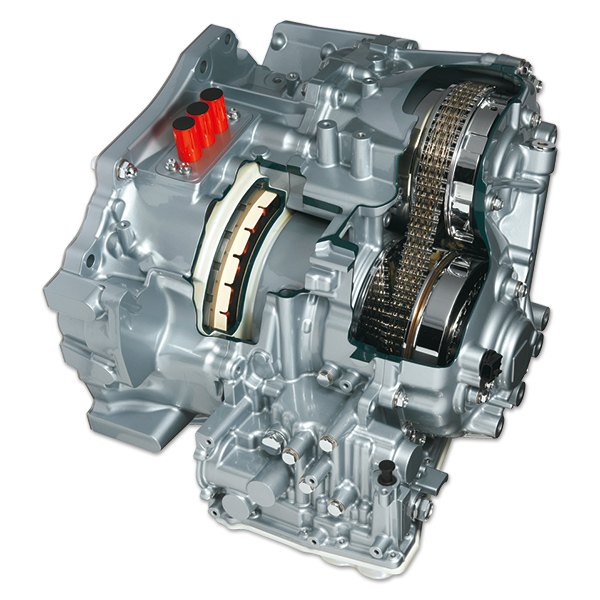

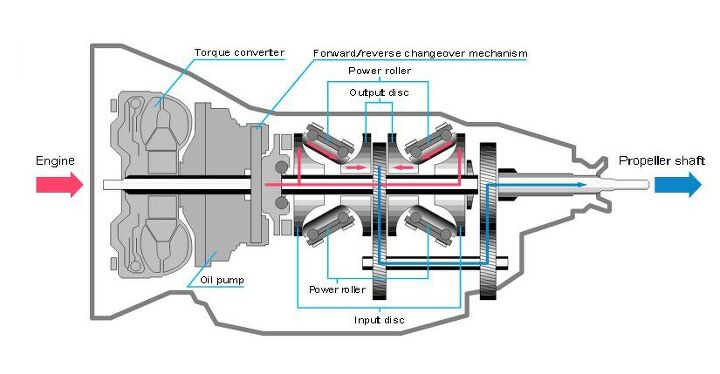

In short one pulley gets bigger and the other smaller. This movement changes the ratio between the two; it’s a brilliantly simple and effective idea that always provides the driver with the proper “gear.”

Now, one of the most complicated parts of a CVT is actually the belt, probably more appropriately referred to as a chain. Paris said “The belts themselves have a lot of work to do, transferring a multiplication of engine torque through the driveline.” He also touched on their cost and complexity, noting that they’re difficult to build and require very tight manufacturing tolerances, something that makes them quite expensive.

These belts are often constructed of a series of metallic segments joined together by metal bands. This design allows the belt to flex yet still transfer torque without ripping apart. Still other CVT designs use chains that consist of innumerable metal links to form a sturdy yet flexible loop. Keeping things simple, some CVTs push while others pull.

BENEFITS

CVTs continue to gain more and more traction in the marketplace. Nissan and to a lesser extent Audi were pretty much on the forefront of this movement but other automakers are jumping on the “belt-wagon” so to speak. Loing said that with their latest models “Toyota and Honda [are] coming to CVT as well.”

There are a couple reasons for this “shift” (no pun intended) in transmission preference. Loing said “the biggest one is fuel economy, the other one is smoothness.” With no preset ratios like a typical planetary-gear automatic he said “[there’s] no torque cut” meaning the power flows in one steady stream as you accelerate – it doesn’t get interrupted by gear changes.

Loing said the reason a CVT is more efficient than a conventional automatic is because “it has the engine operate between the maximum torque and maximum power. By doing this the engine always operates in the optimal RPM zone.”

Additionally Paris said that compared to a typical planetary-gearset transmission “the number of mechanical parts is much lower.” He also said “It’s odd, in a way CVTs are a less efficient design than other transmission types.” According to Paris they have “higher internal friction,” but since they “allow the engine to operate in a narrower rev band” they’re more efficient overall.

Paris said that friction is something companies like Jatco, a leader in the CVT market one of Nissan’s major partners, have been ruthlessly working to reduce. According to Jatco their new CVT 8 model features a best-in-class ratio spread and significantly lower friction compared to previous CVT models.

DISADVANTAGES

Of course everything has its advantages and disadvantages; CVTs are no exception. One of the biggest drawbacks has to do with how much torque they can handle. Loing said they’re typically limited to between 300 and 350 Newton meters of twist. In ‘Murican figures that works out to between roughly 220 and 260 lb-ft of torque.

Another potential disadvantage is mass. Even though they have fewer internal parts Paris said “CVTs tend to be the heaviest of the transmission types.” He also said that due to low adoption rates in the past “[They’ve] been very expensive to replace.”

But what about reliability? Do CVTs have more issues than conventional automatic transmissions? Paris said absolutely yes, noting that there have been a number of class-action lawsuits associated with past units.

But automakers have certainly made strides in improving reliability over the years. In fact Loing said drivers shouldn’t have any issues with CVTs, noting that Nissan backs them up with the same warranty you’d get with a conventional automatic transmission. “There’s no reason why it should be different” he said.

Another downside to CVTs has to do with NVH, that’s noise, vibration and harshness. Due to their limited torque capacity they’re often paired with small, four-cylinder engines. During acceleration CVTs will typically hold a powerplant at a specific RPM, which can create a droning sound and lots of driver irritation.

THE FUTURE

Going forward CVTs are practically guaranteed to continue gaining traction in markets around the world as automakers work to improve fuel efficiency. Japanese OEMs led by Nissan are really pushing them. Loing said “It’s our best selling transmission in North America” noting that “It’s something that’s here to stay with us.”

Nissan is even starting to expand its CVT offerings in the Old World, a market that’s still dominated by manual gearboxes. “We see now even in Europe CVTs coming in the Nissan lineup and associated with diesel” Loing said, noting that the new generation of the company’s Qashqai compact crossover features an oil-burner paired with a CVT.

As it stands today continuously variable transmissions will probably continue their growth in the marketplace. Love them for efficiency and smoothness or loathe them because of droning NVH and possible durability issues they’re not going anywhere.

Born and raised in metro Detroit, Craig was steeped in mechanics from childhood. He feels as much at home with a wrench or welding gun in his hand as he does behind the wheel or in front of a camera. Putting his Bachelor's Degree in Journalism to good use, he's always pumping out videos, reviews, and features for AutoGuide.com. When the workday is over, he can be found out driving his fully restored 1936 Ford V8 sedan. Craig has covered the automotive industry full time for more than 10 years and is a member of the Automotive Press Association (APA) and Midwest Automotive Media Association (MAMA).

More by Craig Cole

Comments

Join the conversation

The discussion about Nissan CVT leaves out the fact that there is a planetary gear set on the output (after the CV mechanism) that provides a high and low range.

I have owned a Toyota Prius C hybrid with an E-CVT since May 2013. It is described in this article, but the illustration to the right of the description is something else, not an E-CVT. It is a remarkably clever design and, apparently, is pretty efficient. Reliability statistics for the car, overall, are very good. I am aware of no common transmission problems. Because it uses two electric motor/generator units instead of belts or clutches, my guess is that it would not be practical to use except in a hybrid. I have been very happy with it. I don't think mine is optimized for hard acceleration, but I haven't really put it to the test. I would buy another.