Common Torque Converter Problems

If you’ve ever driven a vehicle equipped with an automatic transmission, chances are good you’ve been in command of a torque converter.

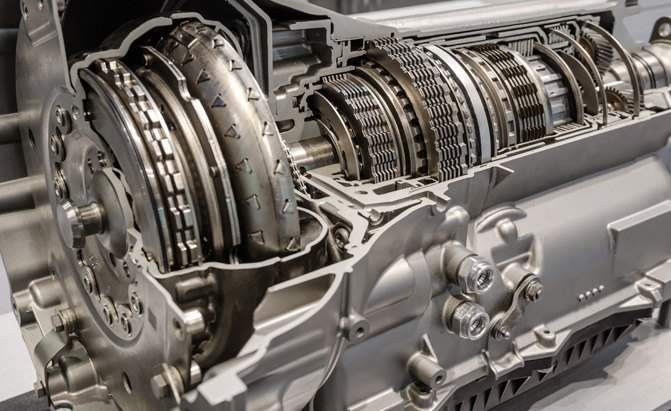

At the risk of oversimplification, a torque converter transfers the power created by a car’s engine to its transmission. It is usually located between the engine flexplate and its transmission, often encased by something called a bellhousing that’s mounted to the leading edge of an automatic gearbox.

Full of fluid, the torque converter is responsible for allowing the engine to move somewhat independently of the transmission. This is why an engine can idle when your car’s wheels and transmission stop, such as when one is at a traffic light.

Common torque converter problems can take many forms, and diagnosing the cause of a wonky automatic transmission is fraught with complexity. The purpose of this post is to help drivers narrow down possible reasons for their transmission troubles and educate themselves before heading to a garage for a repair. Here are a few common torque converter problems you might be experiencing:

Slipping

A few signs indicating a malfunctioning torque converter include shuddering coming from the transmission while driving, gears changing at a higher than normal engine speed, and odd noises such as clicking or whirring.

Since a torque converter is responsible for, quite literally, converting engine torque into hydraulic pressure that’s needed to shift gears inside the transmission, problems in it can cause the transmission to delay a shift or slip out of gear. Slipping can be caused by the incorrect amount of fluid being in the transmission. If not enough or too much fluid is passed to the gearbox, it can cause gears to slip.

Vibrations and Shuddering

If you start to feel shudders when driving at city speeds, like running over rough road or bumps, torque converter problems could be at hand. It generally occurs at part throttle and light acceleration, just before the transmission shifts into one of its top gears.

ALSO SEE: CVT Transmission Pros and Cons

This problem is temperature-related, so one may find it tends to happen on hot days or after idling in traffic for long periods of time. As the transmission fluid cycles around the unit, it picks up frictional heat. Once the amount of heat generated surpasses the transmission cooler’s ability to shed it, the fluid will thin and power transfer will become inconsistent.

Once the transmission fluid has been overheated enough times, it becomes permanently de-polymerized and needs to be replaced. Unless there is physical damage to the converter or transmission, replacing the fluid should solve the problem.

Physical Problems

These issues are generally accompanied by expensive noises. Inside the torque converter are rotating items, two of which are called a stator and turbine. These units have angled and curved blades on them, blades which can break and fail, perhaps due to excessive heat or perhaps due to a metallurgic failure.

In either event, the sudden detachment of a stator or turbine blade inside the rapidly spinning torque converter will do massive and catastrophic damage. A surefire giveaway is a loud whining or screeching noise when the transmission is in a drive gear. It will not likely make any noise in neutral or park. If you experience this problem, haul your vehicle to the roadside the instant it is safe to do so and call a trusted mechanic.

Damaged Torque Converter Seals

The physical part of a transmission that connects to the vehicle’s engine is generally called the bell housing. It earns this name from its shape, which actually does look like an old-fashioned church bell. If transmission fluid is leaking near this area, then it is very possible one might have a damaged torque converter seal.

If a torque converter can’t hold the proper amount of automatic transmission fluid, it won’t be able to transfer power from the engine to the transmission in an effective manner. This will cause all kinds of new problems, not the least of which are overheating and gear slippage (see descriptions above). The bad seal will need to be found and replaced.

ALSO SEE: What’s the Difference Between 4WD and AWD?

Worn Torque Converter Clutch

Less likely, but quite disconcerting if it does happen, are problems presented by a worn clutch inside the torque converter. Automatic transmissions have a number of clutches located throughout the assembly and, in this instance, a torque converter clutch is responsible for engaging direct drive – in other words, a gear.

Remember how a torque converter allowing the engine to move somewhat independently of the transmission, permitting the engine to idle while you wait stationary at a stop light? If a torque converter’s clutch has been spoiled by overheating or been damaged thanks to broken parts whizzing around inside of it, the clutch may not allow disengagement, permitting the car may stay firmly in gear even though the vehicle has come to a complete stop.

Torque Converter Clutch Solenoid

As with most items on a modern car, torque converters do have a measure of solenoids in them that can go bad and fail. The torque converter clutch solenoid is an electronic component designed to control the amount of fluid passed on to the torque converter clutch.

If the solenoid malfunctions, too much or too little fluid will be released, causing abnormal fluid pressures. As noted before, incorrect fluid amounts will cause irregular behavior such as odd shifting patterns and poor fuel economy.

Living in rural Canada, Matthew has immersed himself in car culture for over 30 years and relishes the thought of a good road trip. A certified gearhead, he enjoys sharing his excitement about cars and is very pleased to contribute at AutoGuide. Matthew is a member of Automotive Journalists Association of Canada (AJAC).

More by Matthew Guy

Comments

Join the conversation

I like this reasons