The Best Floor Jacks for All Your Lifting Needs

Most of us don’t start out working on cars in a well-equipped garage. If you were lucky, maybe your parents or a friend had one of the best floor jacks, and you got to use it for your automotive work. But when most projects seem to require buying or borrowing a new specialty tool, a new, high-quality car jack can be low on the list. Impacts, air ratchets, it’s those tools that get the glamour and end up in your toolbox first.

We struggled along for years using either cheap car jacks, or even the scissor jacks that come with most cars, and it was always the worst part of getting a vehicle off the ground. They’re cumbersome, slow, inconvenient, and sometimes dangerous. When we finally upgraded to a real service jack (our Editor’s Pick), it immediately became one of the best tools we ever owned. If you want to get any work done on your vehicle, a floor jack is a must have. These will speed up the process during maintenance like changing tires, brakes pads and rotors, oil, and are vital for larger jobs like suspension work.

There’s a lot involved in picking the best floor jack, such as how much it needs to lift, what material it’s made of, how the saddle is formed, and how tall or heavy the jack is. Floor jacks are designed to help you lift your car quickly, but be sure to be safe in your garage. Not only should you lift your vehicle on flat and level ground, but a major part of safe lifting is to also use jack stands and wheel chocks to stabilize the vehicle. Always push and rock your car around by hand to make sure it won’t fall before you ever get under it. If it’s going to fall, it’s always better to fall when you’re standing beside it than underneath.

These jacks have different weight ratings, feature both aluminum and steel construction, and vary in size, so they can be used under a variety of different cars, trucks, and SUVs. Some of them will even work with ATVs or UTVs, or trailers.

However, a quality, fast-action hydraulic floor jack isn’t always the easiest thing to move around. For more portable units you may want to check out a bottle jack, air jack, or scissor jack. As you’ll see with our Editor’s Pick, many (but not all) brands of jacks appear to be identical, or nearly so, and are made by the same few factories.

Below, you’ll find our picks for the best floor jacks based on our personal experience, features, build quality, and customer service. For more information on car jacks, including use and safety tips, refer to our Table of Contents.

Table of contents

- 1: Editor's Pick: Jegs/Sunex/Arcan 3-Ton Quick Rise Aluminum Floor Jack

- 2. Affordable Aluminum: Torin 1.5-ton Aluminum Floor Jack

- 3. Best for Low Cars: Powerbuilt 2 Ton Extra Low Profile Floor Jack

- Everything You Need to Know About Floor Jacks

- How Big a Jack Do I Need?

- Safe Hydraulic Jack Lifting Capacities

- Why You Shouldn't Trust Hydraulics

- What is a Floor Jack?

- What to do When You First Get Your Jack

- How To Bleed (and Fill) a Hydraulic Floor Jack

- How To Bleed Your Jack Before Use

- Filling a Car Jack With Hydraulic Oil

- Why Buy a Floor Jack?

- How do Floor Jacks Work?

- Mechanical Jacks

- Hydraulic Jacks

- The Different Types of Jacks

- Floor Jack

- Bottle Jack

- Scissor Jack

- High Lift Jack

- The Benefits of a Floor Jack

- Floor Jack Accessories

- What To Look For In a Floor Jack

- How to Jack Up a Car Safely With a Scissors Jack

- Recent Updates:

Why You Should Trust AutoGuide's Product Reviews

We drive the latest new cars, trucks, and SUVs, but did you also know the team at AutoGuide.com tests tires, waxes, wiper blades, and pressure washers? Before we recommend a product as a top pick in one of our popular product lists, our editors put it to the test. We run through all its features, test the claims that the brand makes about each product, and then give an honest opinion on what we like and don’t like from our personal experience. As experts in all-things automotive, from minivans to sports cars, and from portable jump starters to ceramic coating, we want to make sure you buy the product that’s right for you.

1: Editor's Pick: Jegs/Sunex/Arcan 3-Ton Quick Rise Aluminum Floor Jack

This is more than a basic hydraulic jack, designed to lift heavier vehicles with its three-ton capacity. It is constructed from aluminum so it’s 15 to 20 pounds lighter than a comparable steel car jack, making it easier to maneuver around your garage. Our JEGS was advertised at 58 pounds and shows 54.8 pounds on a digital scale; the Arcan is listed at 56 pounds. Maybe yellow paint is lighter than green. They all measures 30 x 13.5 x 8 inches. If you can pick up almost 60 pounds, it has large, convenient handles; otherwise, the casters roll easily.

To raise the 4.5-inch rotating saddle quickly, it’s built with dual pump pistons, while a reinforced lift arm contributes to increased strength, chassis torsion control, and durability. Under load, we’ve found it takes about 10 full pumps to get the full 15.75-inch raise, from 3.5 to the maximum height of 19.25 inches.

There is a rubber insert in the saddle, which isn’t particularly useful; and a foam handle bumper to protect against accidental run-ins with your vehicle, which is useful. The side-mount handles help for convenient positioning, and we haven’t found that they get in the way. Our has performed extremely well, lifting our 4,200-pound Dodge Magnum RT (along with a diesel Kubota utility tractor) easily and dependably.

If you really want to save money, the original manufacturer (which also makes products for Husky, AC Delco, Performance Tool, Craftsman, and many others) will sell you a convenient 300-piece order of them for around $110 each. Plus shipping.

Pros | Good enough for light-duty professional work, 15-3/4 inch lift, 1.5-inches per pump, long handle, one year warranty |

Cons | 56 pounds, large, aluminum casters and wheel get pitted easily, saddle can be too large for some spaces |

2. Affordable Aluminum: Torin 1.5-ton Aluminum Floor Jack

Aluminum floor jacks are a lot less likely to break your back. But in exchange they can break your wallet. The solution is a jack that uses some lightweight aluminum and some cheaper steel. This jack from Torin is one of those and it comes with fewer other sacrifices than similar jacks.

This 1.5-ton jack weighs just 33 pounds. Much lighter than an all-steel jack and about half the price of one made entirely from aluminum. This is a great jack for lower cars, too, able to fit under your car just 3.5-inches off the ground. The jack has dual pistons to make each lifting stroke bring the car up higher. It also has a large rubber saddle that's ideal for stability and great for installing accessories like spacers or pinch weld adapters that let you lift your vehicle even higher.

Then there's the foam bumper to help protect your doors from dings, a side handle to make carrying easier, and the front roller that helps with maneuvering and stability. All with a safety bypass in case you try to lift too much.

Pros | Balances low weight with low price, wide lift range, stable rubber saddle base |

Cons | Compromise means it's not the cheapest OR the lightest, low max capacity unsuitable for larger vehicles |

3. Best for Low Cars: Powerbuilt 2 Ton Extra Low Profile Floor Jack

If you have a lowered vehicle, or just a sports car or classic car, Powerbuilt’s Xtra Low Profile Floor Jack is designed for vehicles as low as 2.75 inches, and it’s capable of raising up to 15.5 inches. It's also a good option if you’ve got a unibody vehicle and you're finding it difficult to position jack stands without accessible frame rails. That’s because it’s equipped with a steel safety bar that slides under the lift arm, securing the jack in its raised position. Although the company says the safety bar eliminates the need for jack stands, we would still use jack stands if at all possible any time we were getting underneath our vehicle.

Other features on this floor jack include a wide base and roller to improve stability, while the ball bearing swivel casters make it easy to maneuver around your garage. A rear carry handle lets you carry the jack to storage when it’s not being used.

The drawbacks are that the all-steel construction adds weight, at 58.7 pounds, and the arm design means you can't get it very far under your car. It is compact and measures 13.4 x 24.7 x 7.75 inches. The saddle is small and doesn't rotate. It has a rubber insert, but they don't last long in any jack. Users report trouble lowering slowly and smoothly; we recommend bleeding all jacks before you use them the first time, or when you have problems. See the Table of Contents for tips on setting up a jack before using it and bleeding it if there are problems.

Pros | Two-ton capacity, very low 2.75 inch minimum height, lock bar for extra safety, one-year warranty |

Cons | One handle to carry almost 60 pounds, not very deep, needs inspection and bleeding before use |

Everything You Need to Know About Floor Jacks

A car jack is an essential part of a DIYer’s garage, and a good one can make a huge difference in how you work on your car. Floor jacks come in a few shapes and sizes and help for both big jobs and small ones. You can certainly just put on a spare tire with your stock scissors jack, but after the second or third time, you'll start looking longingly at a floor jack.

Once you start doing even basic maintenance, repairs, and upgrades, you'll rapidly discover the limitations of a scissor jack. They only work with one specific area of the car, and are often in the way when you're changing the oil or brake pads. Spending several minutes cranking one up and down gets old, fast, and the time adds up. A service jack is also much more stable—there isn't much margin for error with a narrow scissors jack, and your car can fall off if you're not careful.

The best hydraulic jacks are an investment, but when you consider how much you can save over even a few trips to a mechanic for oil changes, or a tire store for changeovers, it makes the decision easy.

How Big a Jack Do I Need?

A good rule of thumb is to stay under 2/3 of your jack's capacity. If you have a 3 ton jack, don't lift more than 2 tons with it. But remember: You're probably not doing anything that will lift a whole car. A new Escalade might weigh 5,800 pounds, but if you're lifting one end of it, that's 2,900 pounds, or 1.5 tons. A bigger jack will definitely make that jacking easier and faster, but a 2 ton jack is enough for the job.

Safe Hydraulic Jack Lifting Capacities

1.5 ton jack |

1,800 pounds |

2 ton jack |

2,400 pounds |

3 ton jack |

3,600 pounds |

4 ton jack |

4,800 pounds |

Why You Shouldn't Trust Hydraulics

It's really tempting when you buy a quality garage jack to let it be all that holds up your car. But it's a rule throughout industry that you should never trust a load held up with hydraulics. Very simply, hydraulics depend on valves and seals to keep the pressure in and if you've ever seen an older piece of construction equipment, you've seen the stains from leaking hydraulics. Generally, these are slow, but two thousand pounds of car coming down slowly rather than fast on your arm isn't much of a consolation.

Every jack will eventually get a leak so bad that it won't hold up a car. That could happen if you haven't used it in a while, and nothing happens when you try to lift. But Murphy's Law says it'll probably be at the worst possible moment. Always have mechanical support for your car when you're under it, whether that's jack stands or just a stack of 4x4s. All hydraulics will eventually fail, and you don't want to be in the way when they do.

What is a Floor Jack?

Rather than lifting straight up like a scissor, high-lift, or bottle jack, a floor or service jack uses an arm to distribute the weight of your vehicle into a frame and across wheels. This makes them more stable than the other types, but also gives them a larger footprint. Leverage against the arm can make lifting a lot faster and easier, taking just five or 10 pumps to lift more than a foot, although how easy or fast it is depends on the car jack you're using. You generally get more speed and with the more money you spend.

The wheels, long chassis, and handle of a hydraulic jack allow you to get one not just under the side of a car, but underneath a frame rail, differential, or other hard point. If you're doing suspension work, you might need to jack up the car, put it on jack stands, then use your floor jack to support the suspension. There are also adaptors to support a transmission, although you wouldn't want to use one regularly.

Mostly, hydraulic car jacks make lifting your vehicle easier, faster, and safer.

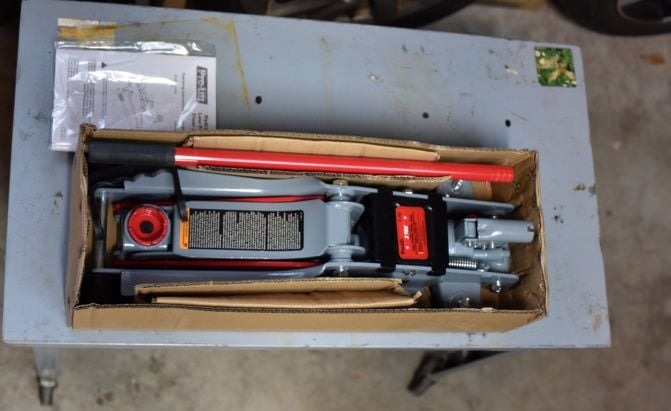

What to do When You First Get Your Jack

Because a hydraulic jack has a cylinder filled with hydraulic oil, they both need occasional maintenance; and often setup, especially after shipping. You're lifting the weight of a vehicle and a lot depends on your jack, so you need to start with a visual inspection.

First, is there any oil on the jack or its box? This isn't necessarily a reason to worry, it's not unusual for a relief valve not to be fully tightened at the factory, or for some to leak out with rough handling. Check your manual for where they are, then tighten any loose valves. If oil has leaked out, you should assume that it's enough that you'll need to top it off.

Next, check bolts, and welds. Welds should make a smooth transition from base metal to weld and back, without any holes, cracks, or pits. Spatter—little droplets of metal that fly off during welding and stick to surfaces—are normal, but a good welder will clean them off. If you're not sure, ask a friend if it's ok. Tighten all the bolts and screws.

Finally, all hydraulic jacks should be bled before use. This just means getting extra air, or air bubbles out. Fortunately, this isn't complicated, you just need to do a lot of pumping. See our next section for how to bleed and fill a jack.

How To Bleed (and Fill) a Hydraulic Floor Jack

Only hydraulic jacks need bleeding, because only hydraulic jacks have oil. It's easy to do, if long and boring, and you usually don't need any tools at all. Start out by unboxing your jack and assembling if necessary, reading the instructions, running through the inspection steps above. Then place it on a flat surface like your driveway or garage floor, with no weight on it.

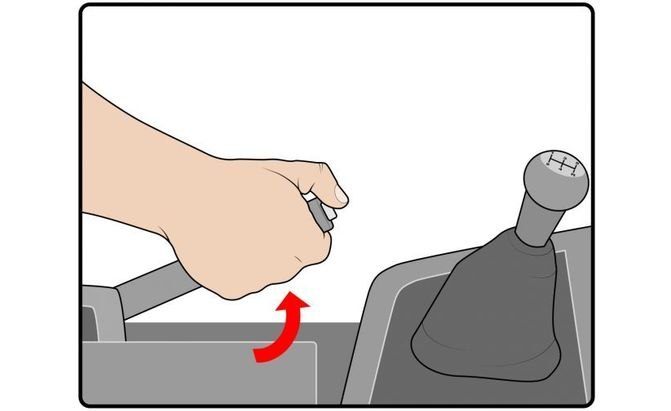

How To Bleed Your Jack Before Use

First, open the lifting valve and pump 10 times. If your jack goes up, your valve is closed. It shouldn't raise up with the valve open.

Second, close the valve and pump it all the way up. Keep pumping another 10 times with it fully raised.

Third, release the valve and let the jack all the way back down. You might have to push it down a little with your foot.

Fourth, repeat twice more. This should separate all the air and oil.

Fifth, if your jack still doesn't lift right, repeat one through four, then with the valve released and the jack all the way down, find and very gently open the filler valve slightly. You should hear a hiss of escaping air. A little hydraulic fluid will probably come out with it. Close it as soon as the air stops.

Filling a Car Jack With Hydraulic Oil

You could need to repeat the whole thing several times. If your jack was low on fluid, you'll need to fill it. Simply locate the filler, either a screw or plug you pop off. If all you see inside is oil, you don't need to fill your jack. If you see metal, that's the top of your hydraulic cylinder, and you should fill your jack with good quality hydraulic jack oil until it's covered (not until completely filled). Replace the plug and then...start bleeding your jack. Again.

If your jack is in good condition, you might go years without bleeding it. If it happens a lot, it's either defective or, if it's older or used a lot, needs to be rebuilt.

Why Buy a Floor Jack?

The last time we had to go to a tire shop to get new wheels and tires mounted, there was a six-week wait. Combine that with paying someone else hundreds of dollars to put on wheels and tires you already own, and a car jack can easily pay for itself.

A hydraulic jack gives you the freedom not only to get things done on your car when you want them done, but opens up the door to all kinds of work short of removing an engine. Almost all routine repair, maintenance, and upgrades can be done at home without too many specialty tools, especially if you have a few friends who can help out. Plus, most parts stores have rental or even loaner tools, if you need them.

How do Floor Jacks Work?

Floor jacks work with either hydraulic power or mechanical power. The latter are typically smaller, lighter jacks and are easy to store, but have a lower lifting capacity and can require a bit of elbow grease to work.

Mechanical Jacks

Mechanical jacks can work in several different ways. Old service jacks like you might have used in a Prewar garage often use a long handle for leverage, and a ratcheting bar. You push down the handle and it clicks forward a notch or two, raising the jack. As far as we know, no one makes a new ratcheting floor jack. They were extremely heavy, and often over four feet long.

However, if you take the same concept and turn it upright, that's the basis of a high-lift jack. Capable of lifting 48 inches or more, these are standard equipment for all off-roaders, who have to cope both with lifted vehicles on large tires; and rough terrain where they might have to jack in while in a hole.

The most common types of mechanical or manual jacks, like the scissor jack included with almost all cars, use something called a lead screw, which is the same concept that Archimedes was playing around with 2,400 years ago, himself having picked it up from an Egyptian water moving method in use around 2500 B.C.E.. A shaft with grooves called threads passes though a ring or collar, and uses mechanical advantage to multiply the force you put in. The disadvantage is you do a lot of turning for not much lifting, but they can be extremely light and compact for their capacity. There are lots of variations on this theme, including ultra-low profile jacks that go as low as 1", and many different style of bottle jacks.

Electric jacks almost always just add an electric motor to a scissor or other screw jack, greatly speeding up the process.

A third, specialty kind of mechanical jack uses a rotating handle to turn a gear box, which lifts a toothed post. They are very slow and have limited range, but they are capable of lifting weights comparable to a bottle jack, up to 50,000 pounds, and there's no chance of a hydraulic failure. The slow raising and controlled lowering can be useful in applications requiring extreme precision.

Hydraulic Jacks

Whether you know it or not, if you're buying a jack, you're probably already using hydraulics. While electric steering and brakes are becoming more common, almost all cars on the road have hydraulic brakes and steering, and often other hydraulic systems, as well. The principle is the same for all hydraulics, whether it's in a jack, a car, an excavator or a Boeing: Generate pressure in a cylinder full of fluid, then send that pressurized fluid somewhere to do work. Hydraulic jacks use a light oil that you pressurize by pumping. Because the oil can't compress much, it has to go somewhere, which is through a one-way check or ball valve into another cylinder and piston, which forces the jack up. You then open a release or bypass valve to let the fluid back out. There may also be an accumulator tank to hold pressurized hydraulic fluid.

Bottle jacks have a slightly different design but operate the same way. The difference is that a floor jack builds pressure before the lifting arm starts to move, and the lifting cylinder in a bottle jack raises as you pump.

There are also air jacks, which can either use compressed air to do the same pumping work on a hydraulic cylinder, or inflate airbags.

The Different Types of Jacks

Mechanical and hydraulic car jacks come in a variety of configurations, each with their own sets of benefits and drawbacks.

Floor Jack

These are what are typically found in garages or workshops. Big and heavy, service jacks are the strongest and most capable car jacks available to the general consumer. Due to their size, it’s unlikely you’d be transporting one of these around in one of your cars for an emergency situation. However, to make moving them around a vehicle easier, they have casters or wheels. As a result, they work best on flat and level ground.

These jacks typically operate with a lever that raises an arm that connects with the vehicle’s jack point and will then raise the vehicle as needed. Then you need to lower it on to jack stands to support the car's weight while you work on it

Bottle Jack

Another more portable jack is a bottle jack, which uses a piston mechanism to raise a vehicle. These can also be pretty easy to use and are often operated with a lever as well. It’s a helpful type of jack, but it’s limited in terms of its height. These can only raise the vehicle twice the height of the device. Additionally, these devices can be kind of tall to begin with, so it might be difficult to put them under sports cars or other lower vehicles. They’re mostly recommended for use on vehicles like SUVs or equipment like tractors.

Scissor Jack

The scissor jack is what most people are familiar with, as they are found in almost all spare tire kits. These are for changing tires, but inconvenient for more exhaustive repairs on a vehicle. Although they’re very lightweight and portable, they are sometimes tiring to use due to the seemingly endless winding required to lift and lower with them.

High Lift Jack

Hi-lift jacks use a fairly simple ratchet mechanism to move the support up a post, rather than pivoting a mechanism off the floor. As a result, they can be as long as you want, although in practice, 60 inches is the maximum. You can't get use them on most cars, as you can't get the lifting platform far enough under the side. Instead, they're used for offroad vehicles with heavy duty metal bumpers capable of supporting the entire weight of the lift, as well as in both first responder rescue, and agricultural applications. These are affordable and versatile tools that can be used for more than just jacking, but aren't very useful for working on regular street vehicles.

The Benefits of a Floor Jack

Floor jacks can be used on a wide variety of vehicle body styles and sizes, and can fit in most garages and workspaces. Sure they’re not as portable as other styles of jacks, but they’re safe and capable.

They are also pretty easy to use. They have wheels or casters to move them around a car, meaning it’s easy to place them under a jack point. Then, using a level and hydraulics, they can quickly lift a vehicle. When you’re done with your work, you can lower the vehicle easily and safely.

These jacks can also be used for jobs like supporting suspension parts, or, with an adaptor, lifting a transmission.

Floor Jack Accessories

Along with your any kind of car jack, there are accessories you'll need to make it safer to work underneath your vehicle.

You should always use a floor jack in conjunction with jack stands, which hold your car up while work on it. Never go under a vehicle that’s only being held up by a floor jack, so jack stands are essential to performing all maintenance tasks. You use a floor jack to raise a vehicle, slide your jack stands underneath the car, and then lower the vehicle onto the stands. Some jack stands are adjustable with a pin, while others are static.

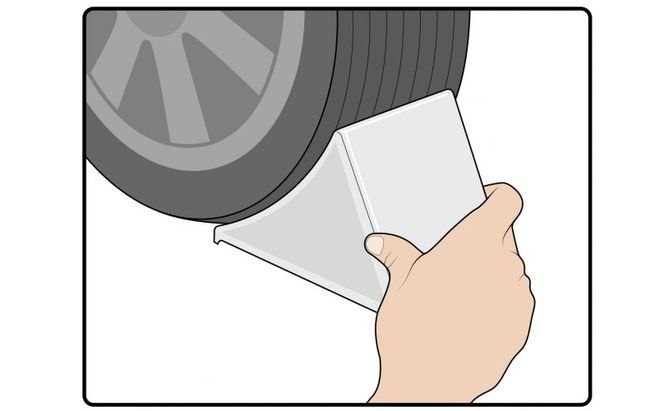

Another important part of using a floor jack is to chock your wheels, which keeps your car from tipping off the jack once you have it lifted at an angle. They are also insurance that the car doesn't roll and drop onto you while you're working.

Creepers and roller seats are useful if you’re going to be working under the car. Roller seats are great when you need to work in a wheel well and don't want to sit on a tire, while creepers let you roll underneath the car. A few days of scrunching around on a piece of cardboard will make most people a convert.

What To Look For In a Floor Jack

There are a few important factors to consider when buying a floor jack. First, what kind of vehicle are you trying to lift? A sports car, sedan, and SUV all need different tools to lift them.

For example, take into consideration the ground clearance of the vehicle. A bottle jack can’t fit underneath all vehicles but may be perfect for a lifted truck. On the other hand, a floor jack would be perfect for a sports car, because many are low profile and can slide right under them.

Another important factor to consider is weight. Jacks are commonly rated by how much weight they can lift and support. So if you have a bigger, heavier vehicle, you need a jack with a higher weight rating. Jacks are most commonly rated for between 1.5 and 3 tons, which should be enough to support most cars. Bigger vehicles like large full-size pickups and SUVs may need a 4 ton jack. It’s also important to realize that the jack won’t be supporting 100 percent of the vehicle’s weight, but it will be doing a lot of work the closer to the engine it is.

One final thing to consider when looking at a jack is what material it’s made out of, and how good the build quality is. Jacks with more metal components, nice even paint finishes, and fancier materials are showcasing their construction, and will likely last longer than models with sloppy paint jobs and plastic components. This item is going to lift your car off the ground, it should be sturdy and robust feeling, rather than cheap and toy like.

How to Jack Up a Car Safely With a Scissors Jack

You don’t have to go to the gym to get jacked, at least when it comes to your car. You just need a solid jack to do the job and you can finally understand all those “bro, do you lift?” memes.

If you want to change tires, brake pads, rotors, or even get to your oil pan to change your oil, then you’ll want to jack up your car. A jack is a handy tool, and many cars come with a scissor jack to help someone change tires, but that kind of jack is only suitable for changing tires and not bigger jobs. It’s not the easiest item to use and doesn’t have a great weight rating. In comparison, a floor jack would do the job much quicker and easier.

But quick and easy is one thing, safe is another. This guide will explain how to safely use a floor jack to lift your car.

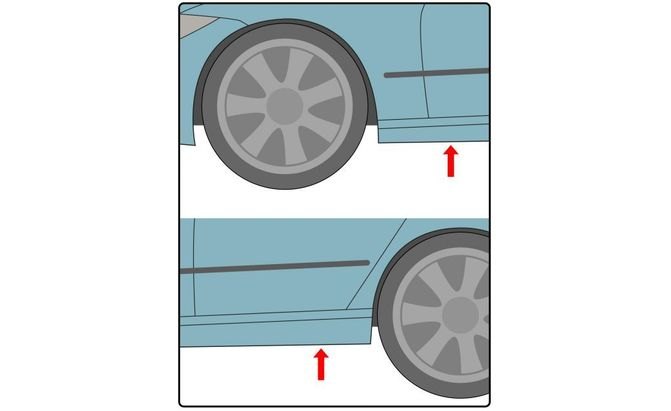

- From there, find your vehicle’s jack point. For the best information on where they are, check your car’s owners manual. Typically, there are at least four of these jack points on a car and they’re normally on the chassis, on the driver or passenger side of the vehicle, and close to the wheels. You can usually spot them because they have a slight indent or perforation along the chassis rail.

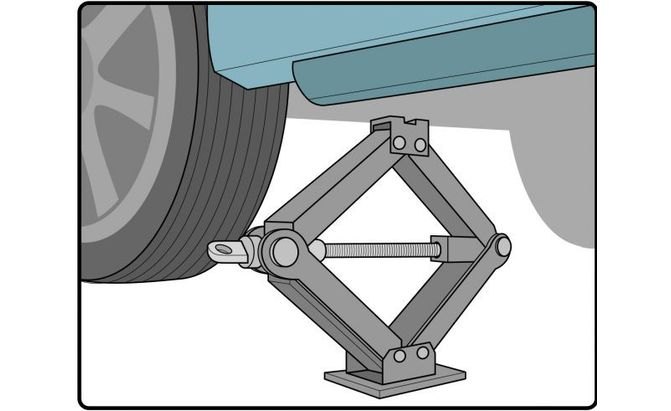

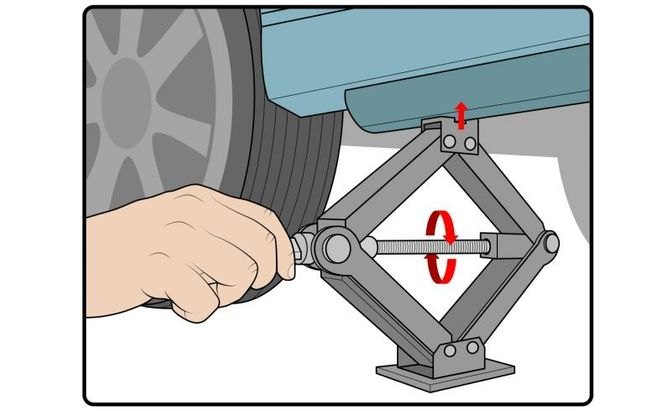

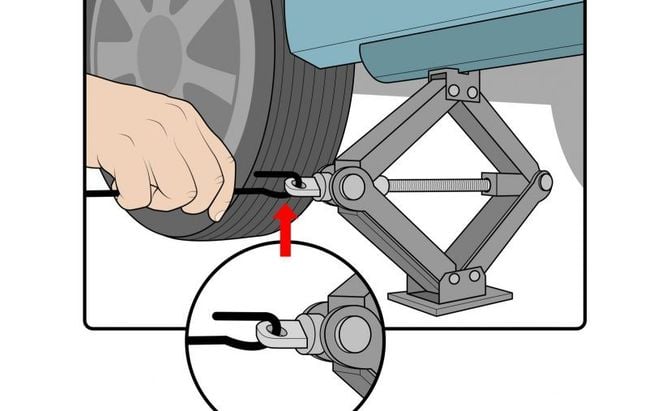

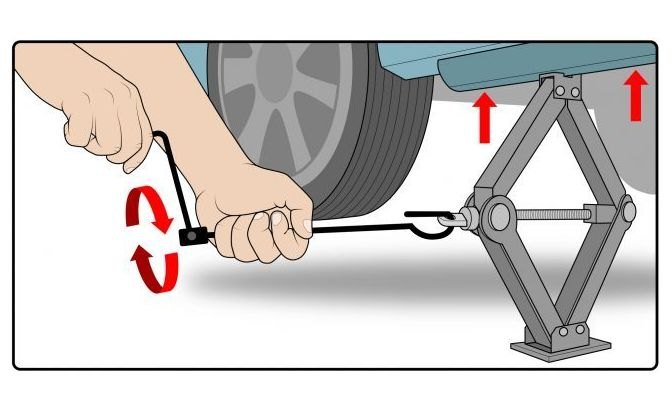

- Line up the jack point to the flat part of the floor jack, and start pumping the lever. This will raise the jack up to the jack point and begin lifting the vehicle. If you’re using a bottle jack instead of a floor jack, then the lifting process is very similar, but if you’re using a scissor jack, like what’s commonly found on spare tire kits, then you’ll need to screw the jack to lift it.

- Once the wheel is in the air, line up your jack stands under the car, someplace close to the jack point. You need to then lower the vehicle onto the stands, either by releasing a valve or using the lever to lower the lift. While it’s on the stands, you’re home free! You can remove the tire as needed or use a roller chair or mechanic creeper to get under the car, and when you’re done, you can raise the jack to lift the vehicle off the stands, then remove the stands and then use the jack to lower the vehicle.

Be sure to remove the chocks before driving the car away after lifting and lowering the vehicle! Or else you’ll be in for a nasty surprise.

Recent Updates:

- March 8, 2024: To provide a better shopping experience, we have decided to reduce the number of recommendations to three. We have re-evaluated our top three picks and they remain the same.

- May 8, 2023: Removed Daytona 1.5 Ton Professional.

- January 3, 2023: Removed promoted product recommendation.

- December 5, 2022: Updated product links.

- November 23, 2022: Removed unavailable Hein-Warner jack, added new photo for Powerbuilt jack.

- October 26, 2022: Updated retailer links.

- August 30, 2022: Updated Jegs jack photo and description, updated How-To sections.

- June 14, 2022: Updated photos for Pro-Lift Jack and How to Inspect section.

We are committed to finding, researching, and recommending the best products. We earn commissions from purchases you make using the retail links in our product reviews. Learn more about how this works.

Photo Credit: David Traver Adolphus / AutoGuide.com

After completing a degree project in automotive design, Dave wrote and photographed for almost a decade in print car magazines (remember those?), before transitioning to digital. He now subjects a series of old high-performance cars to the roads and weather in Vermont and wonders why they're always expensively broken. Please stop when you see him crawling under one on the side of the road.

More by David Traver Adolphus

Comments

Join the conversation