Polestar 3, 4, 5, and 6 Hands-On Previews

Premium EV automaker presents its path forward

Despite having just one car in its lineup currently, Polestar, the premium Swedish EV manufacturer, has big expansion plans that are just beginning to break the surface.

First, its product lineup will triple in the coming year. Its sole production car, the Polestar 2 compact sedan, will be joined in 2024 by two SUVs, the Polestar 3 and 4, which will arrive next spring and summer respectively.

Second, the company’s manufacturing footprint will expand beyond its current base in China, to South Korea and the United States, and it also has some interesting plans for charging, battery technology and autonomous driving.

These topics, and others, were among a company deep dive during its recent Polestar Day, held at the Barker Hangar at Santa Monica airport.

AutoGuide was in attendance, and here’s what we learned during a day of workshops and presentations.

Polestar 5 and 6

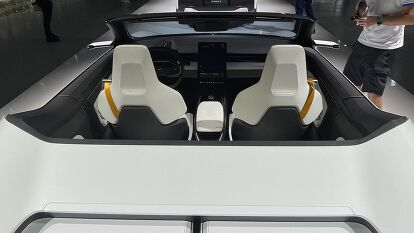

In addition to the near-term arrivals of the 3 and 4, Polestar displayed two other models that are a bit further away. Due to arrive in 2025 and 2026, are Polestar 5, an executive sedan, and Polestar Roadster Concept (Polestar 6), a two-seat convertible.

Both cars were locked, so they could only be viewed and photographed from the outside. Polestar didn’t say much about them during the keynote address either, apart from the fact that they are coming.

New manufacturing sites

During its brief history, all Polestars have been assembled in China, but that will change when production of the Polestar 3 SUV begins next year. It will be built at the company’s plant in Chengdu, China, but will also be assembled at Volvo’s plant in Ridgeville, South Carolina (near Charleston) for the North American market. Volvo is the sister company of Polestar, and both are owned by Geely, a Chinese automotive multinational.

Polestar will also expand its manufacturing base in Asia, when it begins assembling the Polestar 4 SUV in Busan, South Korea in the second half of 2025. The agreement, which is a joint venture between Polestar, Geely, and Renault Korea Motors, will produce the Polestar 4 for North American and South Korean markets.

The Busan site was chosen for a few key reasons, including its direct port access and 23-year vehicle assembly history. It employs roughly 2,000 workers and aims to reduce emissions by 50 percent by 2030 and to become carbon neutral by 2040.

Polestar 4 production is underway at the company’s Hangzhou Bay plant in China for Chinese customers, with global deliveries expected to begin in early 2024.

Autonomous driving

Polestar is working with two other tech companies, Luminar and Mobileye, to bring autonomous driving capability to its production cars, beginning with the Polestar 4. It will be the first production car to carry Mobileye Chauffeur with Luminar LiDAR (light detection and ranging) to offer, “eyes-off, point-to-point autonomous driving on highways, as well as eyes-on automated driving for other environments,” Polestar said in a statement.

Mobileye Chauffeur uses three Mobileye EyeQ6 processors, front facing Luminar LiDAR, and front-facing imaging radar from Mobileye to provide the detection and artificial intelligence (AI) needed to deliver autonomous driving. LiDAR uses lasers to create a highly detailed 3D map of the surrounding environment. The version deployed by Luminar uses technology that delivers both a high level of performance and safety capabilities for production cars, according to Polestar.

V2G

One of the more interesting topics discussed during Polestar Day was V2G, which means vehicle to grid. As the name suggests, it means a vehicle’s battery can not only charge, but also discharge. The discharged energy could then be used to help power a home or electricity grid.

Polestar is working on a large vehicle-to-grid pilot project in Gothenburg, Sweden, which is using a fleet of Polestar 3 cars and is funded by Swedish Innovation Agency Vinnova. With local and national partners, including the Swedish National Grid Authority, Polestar aims to find commercial applications for V2G that can be used at scale.

Polestar is also forming a collaborative project with the California Energy Commission and the non-profit energy institute EPRI, also funded by Vinnova, for a pre-study that will create a plan for implementing V2G services in California. The pre-study begins next month and runs through October 2024.

Polestar is also developing a Virtual Power Plant (VPP) that links all its test fleet cars connected to the grid. The cloud based VPP then calculates the total capacity of the fleet’s batteries and will automatically charge or discharge depending on the grid’s demand and battery needs.

StoreDot XFC

During Polestar Day, the assembled press learned more about StoreDot, an Israel-based battery tech company working with Polestar to bring the former’s fast-charging batteries to the automotive industry.

StoreDot’s extreme fast charging (XFC) technology, also known as “100-in-5”, can produce 100 miles (160 kilometers) of range in a five-minute charge. It doesn’t require a specific battery-pack format, but will instead work with existing designs, according to StoreDot.

StoreDot conducted several of its pouch cell demonstrations in Santa Monica, alongside a Polestar prototype battery module using XFC technology. A full-scale demonstration of XFC in a Polestar 5 prototype is slated for 2024.

Before wrapping up, I’ll mention that AutoGuide did get some seat time in both the Polestar 3 and 4 in Santa Monica. Neither car was available for driving, but brief, roughly 10-minute, ride-alongs were offered. Both cars were European-spec pre-production units that are being used for testing and validation around the world.

Not much could be drawn from either experience, but both cars generally felt comfortable, and were quite fast at times. We look forward to spending more time behind the wheel of both next year as they move closer to launch in North America.

Become an AutoGuide insider. Get the latest from the automotive world first by subscribing to our newsletter here.

With more than 20 years of industry experience, which includes automotive retail, motorsports PR, and writing and editing for various automotive publications, Lee is an AutoGuide freelancer, and car guy to the core. For nearly a decade and a half, he has married his two consuming passions together – journalism and the automotive industry. Whether it’s providing coverage on debuts from an auto show floor, writing road test reviews, or previewing a new model coming soon, Lee is eager to share his passion for the automotive industry with his readers. He is a long-standing member of the Automobile Journalists Association of Canada (AJAC) and won a feature writing award in 2018.

More by Lee Bailie

Comments

Join the conversation